In the spring of 2021, Copenhagen pump entered into a collaborative project, around pumping bio-fluid for a dry matter measurement of a complex liquid. For energy reasons and measurement reasons, it made the best sense to raise the pressure on a representative partial stream and not the entire production flow.

The advantage of using an Allweiler eccentric smart pump is precisely that the flow is cash regardless of pressure variation and depends solely on displacement and speed.

At the same time, the pump can handle varying viscosity, dry matter and other fluid-related characteristics without compromising capacity. It is this characteristic that makes the excenter snekke pump very suitable for bypass pumping.

Dry matter measurement in complex liquids.

Complex liquids are liquids that are composed of more character traits than a traditional Newtonian liquid. Household-based bio-waste from home green bags is reprocessed into a homogeneous liquid in special plants. In the process, the bio-waste is transformed into a valuable finished product, where the carbon compounds of the dry matter can subsequently easily be converted into bio-fuel or biogas. It is therefore of great interest to both the producer and the purchaser to be able to determine the dry matter content accurately quickly. In the process, the waste is converted into a complex liquid, i.e. a liquid containing air, which gives rise to misalenment, since the dry matter meter sees air bubbles as dry matter.

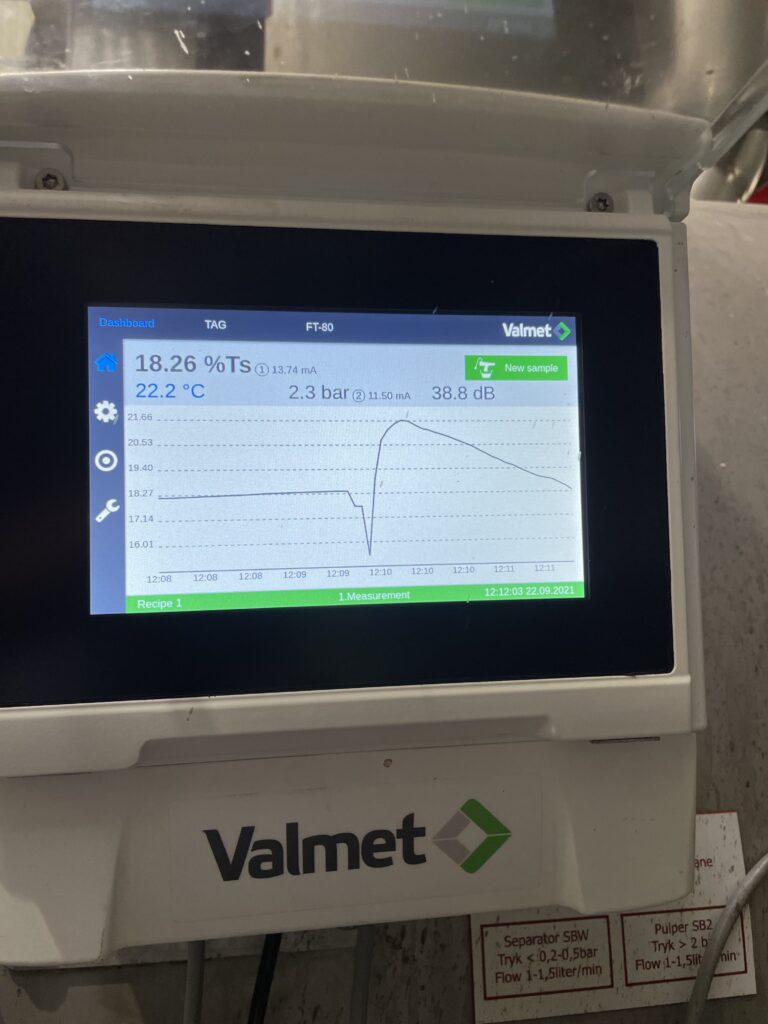

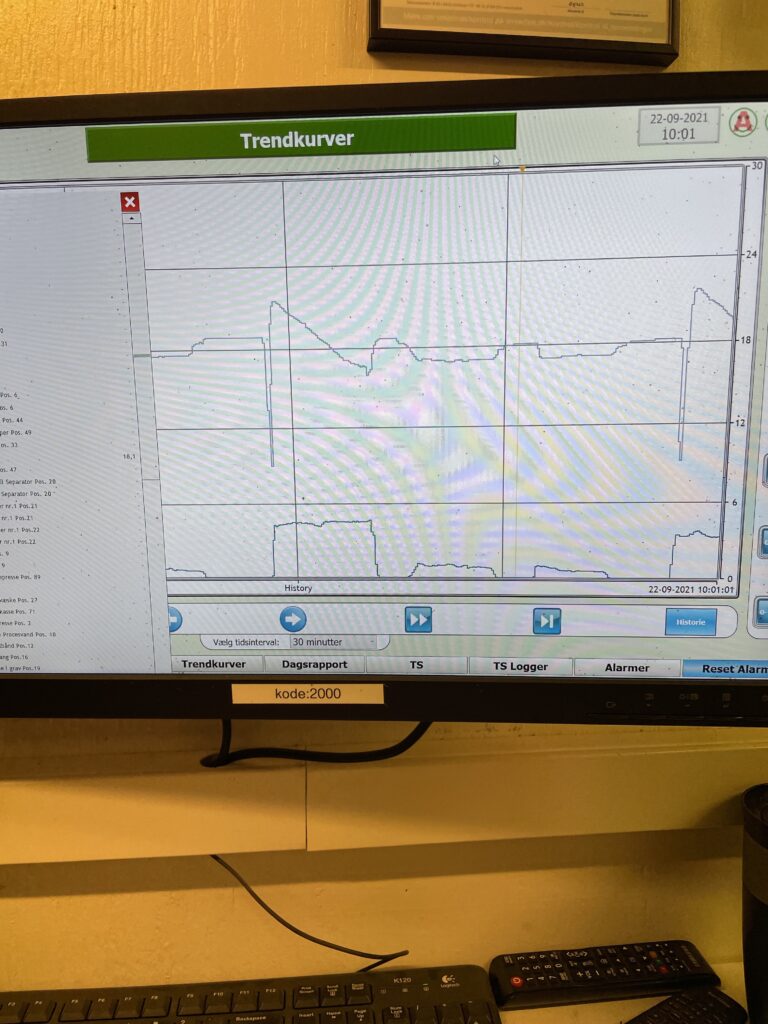

The bypass-based dry matter measuring system from Lisco/Valmet (microwave based meter) and a bypass pump from Allweiler ensure that the air bubbles are reduced so that they no longer interfere with the measurement. At the same time, it ensures that the measurement is done with a controlled low energy consumption. The accuracy of the measurement is with the lab. test checked better than 1%.

On the below you tube video, application engineer Jens Poulsen from Lisco explains system most construction.

Project: Bypass Pumping

Fluid: Bio sludge

Capacity: 2-500 l/min

Pressure: 0-6 bar

Viscosity: Varying 100-1000 mPas

Dry matter content 10-22%