Copenhagen Pump blev 2023 bedt om at finde og levere en ny kalkdoseringspumpe til erstatning for en eksisterende peristaltisk pumpe.

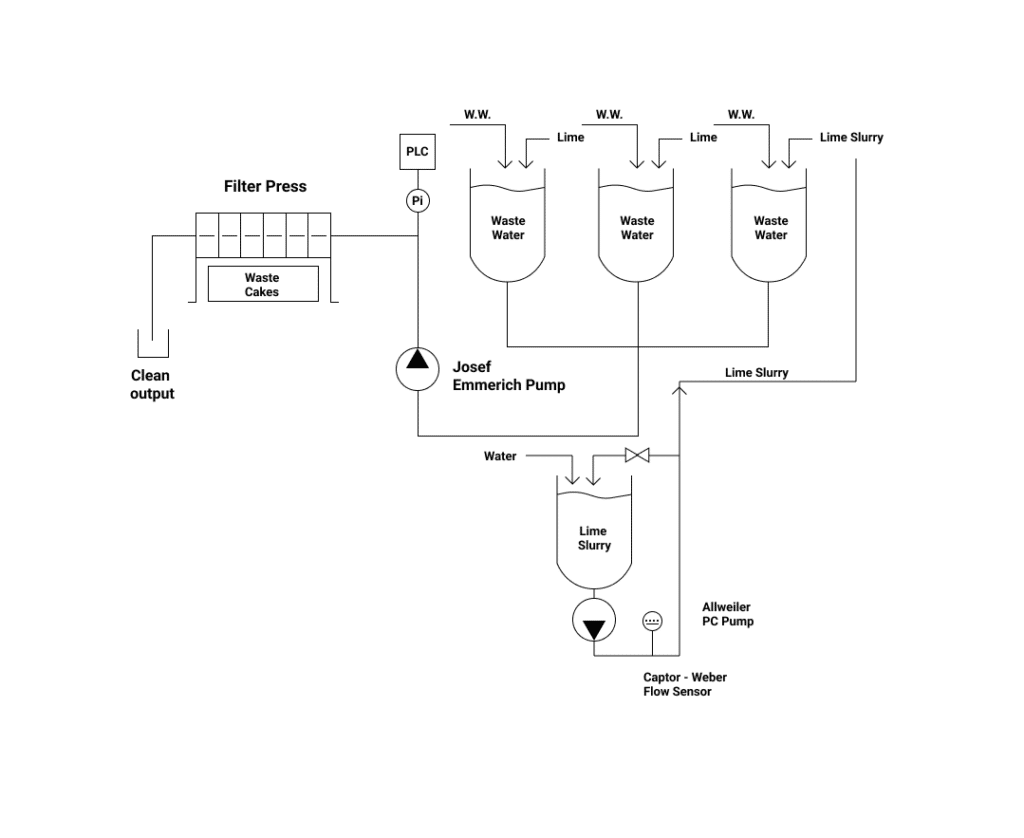

Kalken som opslæmmes i vand med omrører, holdes desuden cirkuleret i kalkbeholderen indtil at den skal anvendes til flokkulering af industrispildevand. Industrispildevandet flokkes for at binde skadelige partikler som man ikke ønsker udledt til kloak.

Bindingen af kalk til partiklerne fungerer ved at det giver partiklerne overflade nok til at det efterfølgende kan filtreres. Cirkuleringen sker for at produktet ikke skal bundfælde efter oprøring.

Allweilers ekscentersnekkepumper er en positiv fortrængningspumpe som udmærker sig ved at være særdeles trykstiv og pulsationsfri. Den egner sig derfor til at pumpe næsten alle medietyper lige fra vand til meget trykke væsker.

Klik på tegning for zoom

Væsker med partikler eller følsomme partikler, håndterer Allweiler pumpen meget nemt, da det foruden at være en stærk pumpe også håndterer pumpning meget produktskånsomt. Pumpen er desuden enkel og billig at vedligeholde.

Da Allweilers ANBP pumpe en positiv fortrængningspumpe uden en sikkerhedsanordning, bør pumpen overtryksbeskyttes og tørløbssikres. Ved tørløbssikring forstås en anordning som forhindre pumpen i at køre tør for væske eller ikke at starte op uden væske. Til dette formål monterede vi en Weber Captor flow switch. Flow Switchen fungerer termisk. DVS at en lille energimængde føres til et bulbhoved som registrerer afkølingen som følge af et forbi-strømmende flow.

Instrument er skalainddelt 0-100 pct med 10 intervaller belyst af led-indikatorer. Setpunkt og hastighed indstilles ved kommissionering på to nemme drejeknapper. Falder flowet under drift giver instrumentet besked til et motorværn som så bryder motoren, det samme sker ved forsøg på opstart uden væske.