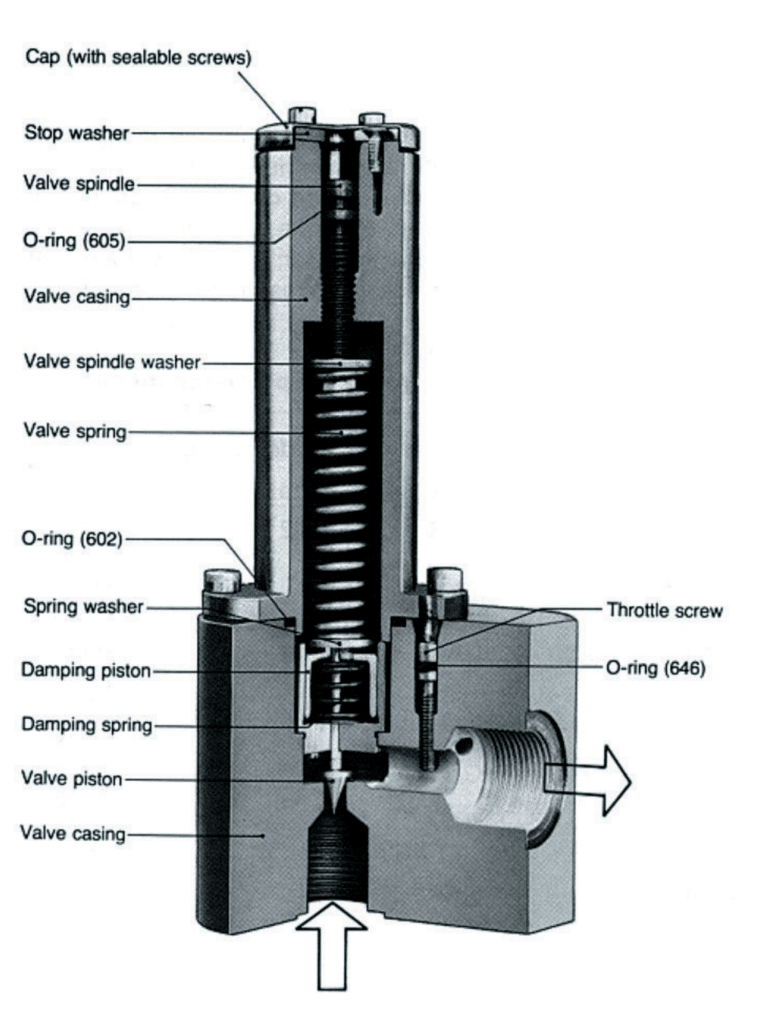

IMO Circor type GA Bypass ventiler GAR, GAS og GAD.

IMO ab tilbyder en særlig enkeltvirkende bypass-ventil til brug i hydrauliske systemer, hvor man ønsker et sikkert og nøjagtig åbningstryk. GA ventilen har en indbygget automatisk hydraulisk virkende trykkompensator, som sikrer meget lave trykstigninger og trykvariationer i tilfælde af åbning. Dette gælder både for åbning og for den dæmpede lukningsproces. Ventilen er således konstrueret med henblik på ikke at skabe uhensigtsmæssige trykstød eller trykvariationer under åbning og/eller lukning.

Version: IMO GAR, GAS og GAD.

Anvendelse:

IMO GA ventiler er tiltænkt brug i oliebaserede systemer som sikkerhedsventil eller bypass ventil dvs. at ventilen kan bruges som en arbejdsventil*. Ventilen justeres til åbningstryk vha. fjederspændingen og dæmpes vha. Trottle skruen. Under gennemstrømningsdrift er ventilen således i hydraulisk balance.

*Det er dog en betingelse at bypass ventilen ikke er udsat for pulserende flow hvis den skal fungere som arbejdsventil. Pulserende flow kan eventuelt dæmpes ved hjælp af pulsationsdæmpere.

Installation:

I henhold til Manual side 2 dog anbefales tæt placering i forhold til trykgiver (pumpe), samt oliefyldt rør for sikker performance. Vand eller kemikalier er ikke forenelige med GA ventilerne. Vand bør således ikke bruges som testmedie.

Da der afsættes stor mængde energi i væsken gennem ventilen, anbefales det ikke at lave bypass til sugesiden af pumpen, men i stedet retur til tank.

Der henvises til teknisk brochure GA 1102 GB for fri download.