Netværksprojekt Power to X Siemens Germesa/Teknologisk Institut.

Beregning af kølevandbehov, varmeveksler og pumpeteknik i forbindelse med Power to X (herefter benævnt PTX)

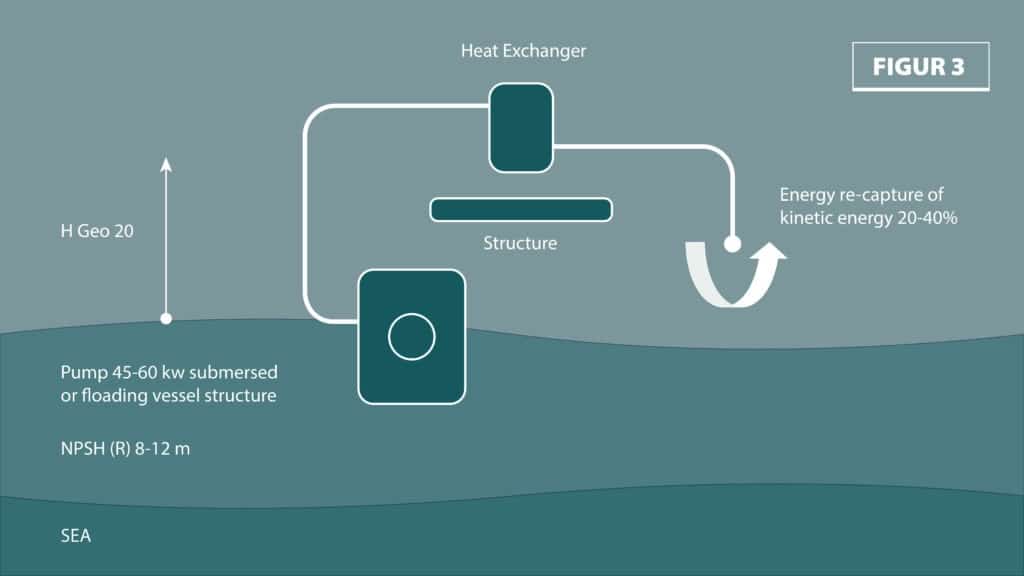

Under projektledelse af Teknologisk Institut beregnede Copenhagen Pump kølevandkravet til køling af det varmetab som fremkommer ved elektrolysefremstilling af Brint/Hydrogen (H2). Vi vurderede MTBF Mean time between failures for en anlægslevetid på 25 år samt og de hydrauliske udfordringer som Open Loop og Closed Loop systemer medfører.

Beregningerne blev foretaget på et 500 MW og et 21 MW PTX belastning af havvindmøller.

Vha. de 3 nedenstående skitser forklarede vi fordele og ulemper. Vi gav anbefalinger til pumper og varmevekslerløsninger, anskuelig gjorde C02 foot print, energitab, vedligeholdelse m.m.

De to varmevekslerløsninger som vi vurderede, var hhv. en traditionel pladevarmeveksler (open loop) versus en nedsunken rørkøler (closed loop). De pumpeløsninger og hydrauliske udfordringer som afledt heraf, har vi ligeledes forholdt os til.

I projektet har vi involveret ledende eksperter fra producenterne, fra vores private netværk, rådgivende ingeniørvirksomheder og universiteter i udlandet med speciale i relevant fysik.

Vi arbejder ud fra en model hvor vi danner os et overblik over den relevante fysik, kommercielle behov og afleder herfra de tekniske udfordringer og tekniske løsninger. Vi har særlig fokus på udnyttelse og omsætning af energi og vedligehold.

Nedenstående ses dele af konklusionen:

Konklusion:

Skrevet af Thorbjørn Schrøder General Manger Copenhagen Pump

Maskinmester/EBA.

Pumper, pumpeteknik, hydrauliske betragtninger, Søvandskøler, begroninger, vedligehold, energiforbrug.

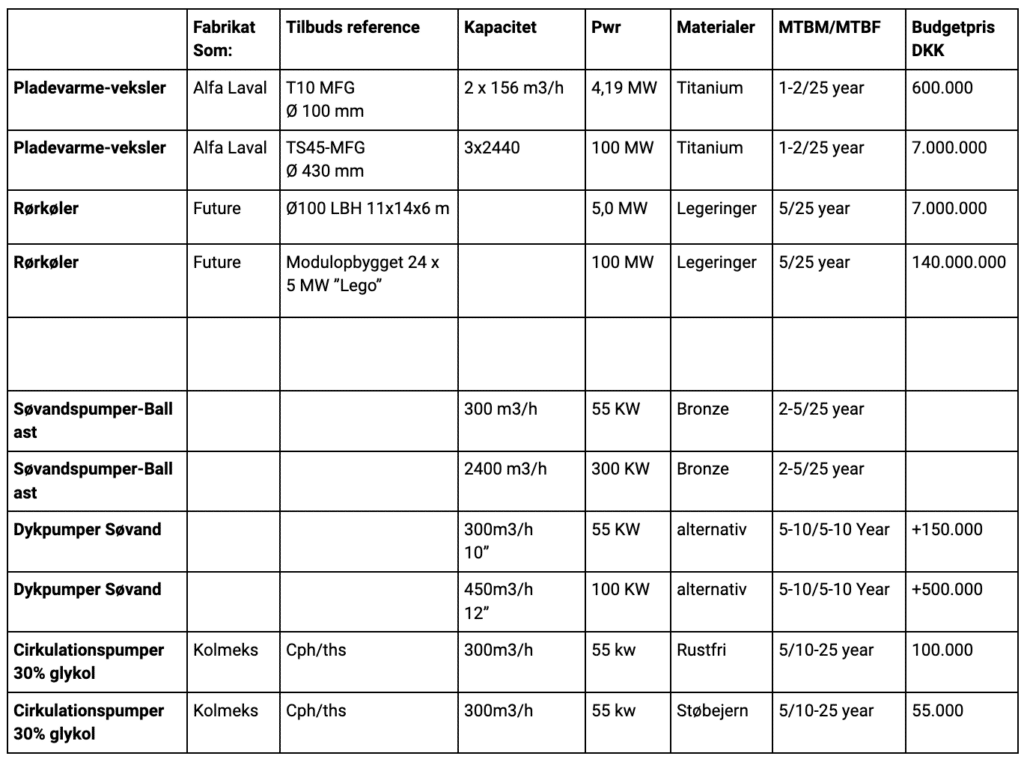

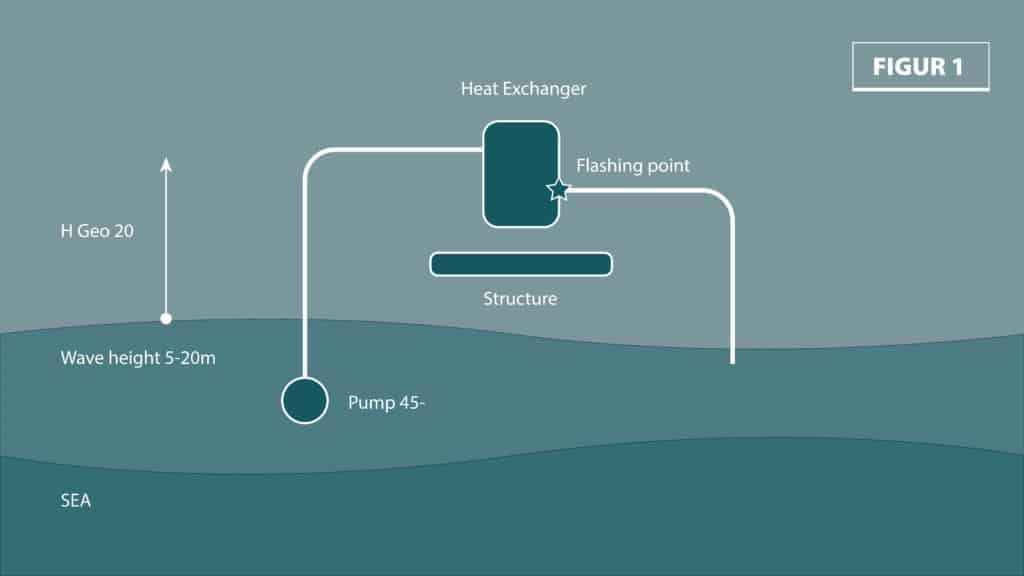

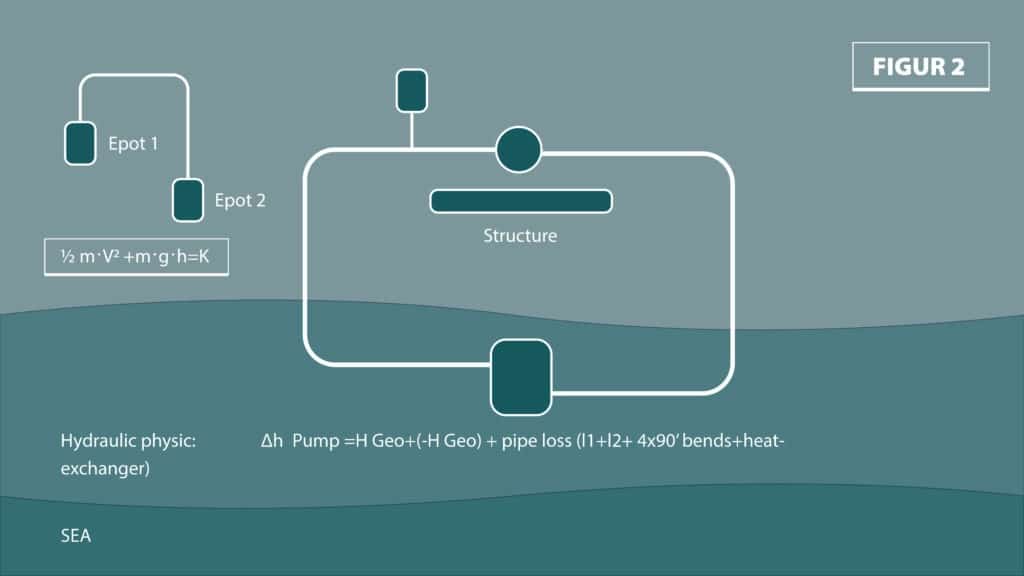

Med baggrund i opdraget fra Teknologisk Institut 500 MW(h) PTX anlæg ved Siemens Germesa/ Green Hydrogen, har jeg undersøgt forskellige teknologier og udfordringer baseret på open loop og closed loop illustreret ved fig1, fig2 og fig3.

Da der ikke har været andre tekniske data til rådighed har jeg med baggrund i 500 MWH forudsat 2 grundlæggende belastningsscenarier

A)500 MWh over 24 t

B)500 MW konstant belastning.

Kølevandstab 20% af den producerede effekt

Søvands delta P 12C

Kølevands/Glykol 30% delta T 60-40C

Geometrisk løftehøjde 20 m

Friktionstab 1 bar

Beregnet pumpeeffekt ca 1 MW svarende til 1-2/1000

Ved almindelige kalorimetrisk beregning Q= MxCxΔT, fås med disse forhold 71,6 m3/h pr 1 MW køleeffekt

500 MWh over 24 t (20,83 MW) giver et kølevandstap 4,16 MW,

svarende til kølevandsforbrug på 297 m3/h

500 MW giver et kølevandsforbrug på 7128 m3/h til 100 MW kølevandstab.

Pumpeeffekten andrager ved 3 bar ca. 1 MW hvor ved at man ved closed loop kan spare 2/3

Ved en elpris på 1 kr og 8760 t/år svare det til en driftsomkostning på 1000DKK/time eller ca 9 mil.og besparelsen vil være ca DKK 6 mil. Den simple tilbagebetalingstid udgør således 23 år, dog uden hensyntagen til andre omkostninger, det vil kræve en omfattende teknisk analyse at vurdere alternativernes omkostningsstruktur korrekt. Man skal dog være opmærksom på at lovmæssigt forbud mod Open Loop slet ikke er usandsynligt.

Kølevandsforbruget kan opdeles over decentrale anlæg hvor hver mølle eller få møller har sin egen selvstændige kølekreds af 297 m3/h eller man forstiller sig en central kølecentral/produktions platform a 7128 m3/h.

For begge scenarier gælder at man skal vælge mellem to teknologier A) Open Loop B) Closed Loop

For Open Loop fig 1 gælder at den kinetiske energi ikke let og billigt kan tilbageføres og i praksis betyder det at man skal betale den for den geometriske løftehøjde i eksemplet 2o m.

Den fysiske argumentation findes i den mekaniske fysik om tryk og varmelære hvor damptrykket på -1 bar fås ved – 10 m, hvorved de to væskesøjler mister hinanden. Vand evner at optage trykkræfter, men ikke trækkræfter. Det er en fejl som kan overses, da man også i open loop systemer kan fratrække faldhøjden for systemer med mindre end 10 m delta H. Således fungerer en hævert.

For Closed Loop fig 2 gælder at de to gometriske løftehøjder går ud med hinanden og man således alene skal betale for friktionstabet.

Den fysiske argumentation findes i loven om energiens bevarelse.

Det er teoretisk muligt at generhverve noget af den kinetiske energi i bunden af open loop med en turbine. Fra teori om omsætning af kinetisk energi i vingetrukne maskiner erfares, at man maksimalt kan omsætte teoretisk 60 % af den kinetiske energi og i praksis for små maskiner langt mindre, det er derfor ikke kommercielt realiserbart at forsøge sig med energy recapture som vist i figur 3. Der findes dog udstyr til dette formål, det er typisk propeller turbiner.

Varmevekslere:

Jeg har talt med en producent af pladevarmevekslere Alfa Laval og de to kølevandsscenarier er absolut realiserbare og kendt teknologi fra henholdsvis olieindustrien og skibsfarten. Mht. vedligehold og levetid 25 år må, årligt tilsyn adskillelse og mekanisk rengøring/højtryksrensning forudses 1-2 år.

Termisk fungerer teknologien godt og er kendt teknologi. Begroninger mellem pladerne vurderes ikke højt af fabrikanten mens det i indløbet vil være mere typisk og det anbefales montere evt. Automatisk/sekventiel back flushing udstyr.

Min overordnede vurdering og erfaring med pladeveksleren er, at det er en solid løsning.

Priser

4-5 MW 300 m3/h DKK 600.000

100 MW 7-10000 m3/h 6-8.000.000

Søvandspumper:

Der findes to muligheder for at etablere søvandspumper.

Der er fordele og ulemper ved begge løsninger. Levetiden for den dykkede pumpe er typisk noget kortere og ikke vedligeholdesfri.

Den traditionelle ballast/brand/søvands pumpe i bronze holder typisk i 25 år med periodevis vedligehold på akseltætninger.

Pumperne fås op til ca 2400 m3/h hvor 4 pumper således kan dække 500 mw behovet på 7-10.000 m3/h

300 m3/h pumper til 20 mw behovet er helt standard skibspumper med 55 kw elmotorer.

Såfremt man vælger en central løsning med 7-10.000 m3/h, er min vurdering at en skrogmontage* under vandlinjen, af få store pumper, vil give den mest problemfrie pumpeløsning**, mens den decentrale løsning nok lettere løses med 10-12” dykpumper.

*mfb for bølgehøjde, byggehøjder og teknisk løsning i øvrigt. Evt. overvejelse om flydende platform eller skib, frem for stående platform. Denne løsning kan evt. også tænkes sammenbygget med new clear og kompressionsanlæg til højtryksbrint evt. til transportsektoren og placeres i forbindelse havne. Vi har i Danmark tradition for skibsbygning, skibsdesign af specialskibe og flydende fabriksanlæg. Behandles ikke yderligere her i denne rapport.

**I udgivelsen offshore vind solution er vist eksempler på flydende structures.

Sea Bed Cooler:

Futures submersed Sea Bed Cooler er en rørkøler-konstruktion som stilles på havbunden. Systemet gør det muligt at anvende closed loop teknologien fig2, hvorved man sparer en stor del af pumpearbejdet. Man sparer søvandspumperne og kan indsætte en god inline pumpe i simple metaller, med en god akseltætning.

Ifølge Future er rørkøleren udført i legeringer som forsinker/hindre begroninger og en 5 årlig højtryksrensning på bunden er til strækkelig (dykkerarbejde). Anskuer man f.eks. galvaniserede konstruktioner finder man en reduceret begroning sammenholdt med f.eks. ubehandlede glasfiber eller træskog. Efter samtale med Future lyder det sandsynligt og de har proof of concept i Norge. Ifølge Future er der i den Tyske del af Nordsøen, nu forbud mod at anvende open loop systemer. Overordnet set er min vurdering at teknologien giver rigtig god mening. Det indhentede tilbud er en 5 MW køler og koster ca. 10-12 millioner NKK hvilket er en faktor 10 i forhold til pladeveksleren. Energimæssigt, vedligeholdelsesmæssigt er det min vurdering at fordelene opvejer ulemperne og nok også anlægsomkostningerne, som kan udføres teknisk ”simplere”. Jeg har ikke forholdt mig til prisen på rørkøleren andet end at den er en faktor 10 højere end pladekølerens, men prisen afhænger formegentlig af flere faktorer, som skal vurderes i en mere kompleks analyse i stor skala. Grundlæggende er ideen god, idet den har et lavere co2 footfrint, ikke kræver udledning af giftstoffer og har et lang driftstid MTBM 5 år.

Begroninger generelt:

Det er min erfaring at begroninger i høj grad hænger sammen med materialer og hastighed. F.eks. begroes messing propeller som sejles ofte, typisk ikke på de dele hvor hastigheden øges som følge af diameterøgning, mens man ved centrum, ser få begroninger. Sejles propellen ikke, begroes hele skruen hurtigt. Der findes kemiske løsninger i form af kobberbaseret maling, elektrolyse af hypoclorit, Zink mv som er kendt kemisk behandling.

Ifølge Alfa laval er strømningshastighederne mellem pladerne så intense at begroning af ruer ikke sker imellem pladerne, mens almindelig tilsmudsning må kunne forudses. Producenter af pasteuriseringsanlæg til ballastvand melder ligeledes om meget lange driftsintervaller af pladevekslere i deres anlæg. Dette tyder på at høj varme har en gunstig bekæmpelsesvirkning.

Søvandsystemer på skibe behandles typisk ikke kontinuerligt kemisk mens de sejler. Der er dog i nogle tilfælde en dimensioneret overkapacitet af søvand på 300%. Søvandskølerne trækkes typisk 1-4 gange årligt afhængig af fartområder og højtryksrenses.

Ukritisk brug af kemisk behandling bør nok underkastes en nærmere analyse.

Kølevandspumper ferskvand evt. tilsat glykol:

Vi har 3 års positiv erfaring med Finske Kolmeks pumper fra bremsesystemer i vindmøller. Vi har med denne type pumper ikke haft vedligeholdelses eller driftsrelaterede nedbrud og forventer en MTBF faktor på min 10 år. De skyldes at pumperne er godt afbalancerede og anvender den bedste enkeltmekaniske akseltætningsteknik. Fra landinstallationer ser vi ligeledes meget lange intervaller i kølevandssystemer. Pumperne er inline pumper og har dermed et meget lille foot print. Samme pumper kan i øvrigt anvendes til pumpning af lud i forbindelse med elektrolysen, alternativt anvendes magnetkoblede pumper eller spalterørsmotorpumper som er tætningsfrie.

FW.Kølevandspumpe i rustfrit stål 300m3/h x 55 kw andrager DKK 100.000

FW.Kølevandspumpe i støbejern 300m3/h x 55 kw andrager DKK 55.000

Tekniske løsninger: