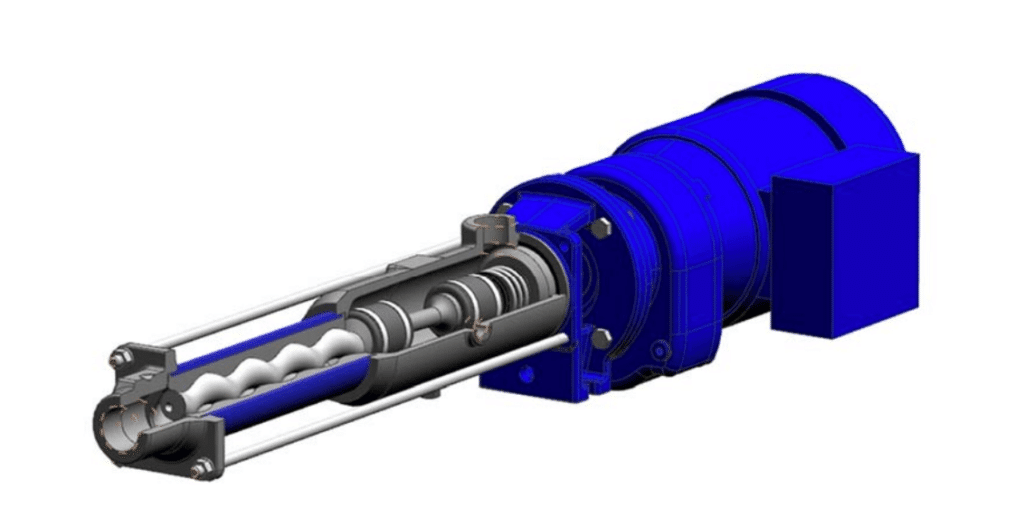

Allweiler has just launched their brand new dosing pump, AEB-DE.

During the development of the new pump, work has been done to combine Allweiler's extensive experience with new market requirements and customer needs.

The AEB-DE pump is available in a compact block design in four different sizes (1.3, 2.3, 5.3 and 12.2). However, a foundation plate can be added as an optional extra. The connections to the pump can be selected in either a thread or flange version.

To achieve wide market coverage, the pump housing will be made of high-quality stainless steel. This choice of materials makes it possible to use the pumps in a wide range of applications. By default, the suction housing has three more closed drilling compounds to ensure a flexible use of the pump. The suction casing can be rotated 90°, while the pump can still be drained safely. In addition, these drilling compounds can be used to add sensors, flush or fill the pump

Another improvement is the location of the mechanical shaft seal, which is now provided as standard. The shaft seal is located within the liquid flow, ensuring that it is permanently rinsed and cooled. This makes it possible to install the new AEB-DE both horizontally and vertically without any risk of a dry-run of the mechanical shaft seal. If necessary, a rinse can be offered as an option for the shaft sealing or alternatively, the pump can be equipped with an old-fashioned cord can.

To ensure safe pump operation, the new dosing pumps can be upgraded with a dry-run fuse (ATLS-T1) or a pressure sensor (ATLS-P).

The conceptual design phase has been approached with an innovative approach. The new series has only four different sizes and replaces the six sizes of ADP/ADBP and ANP/ANBP that will be phased out. With their optimized geometries, the new pump can handle the same range of operating data without any limitation.

Another advantage of AEB-DE is that all four sizes have identical installation dimensions. The only difference is a variation of the transport elements (Rotor &Stator) and the use of adapters inside the pump. This flexibility allows for a variation in flow rate by simply replacing transport elements without requiring cost-intensive renovations and installation adjustments such as pipe changes etc.

The following pump documentation has been created:

For new customers and new RFQs, the new pump must be selected.

From 1 April 2020, only AEB-DE will be offered to give existing customers sufficient time to switch from the outdated to the new series.

With the introduction of this new pump, the old SERIES ADB/ADBP and ANP/ANBP will be phased out. They will only be available as replacement pumps until 31 December 2020. Spare parts will be available without any restriction.

Although it is two different series that have been consolidated into a new pump, the same range of flow rates can be handled. In addition, the application fields are expanded and create incremental customer benefits (e.g. vertical installation, identical installation space for different sizes).

Based on technical improvements and changes in the joints and sealing, it was not possible to achieve a dimensional interchangeability.